|

| December 14, 2021 | Volume 17 Issue 46 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Researchers work out how to increase endurance of stainless steel

A team of scientists from Russia, Italy, and Turkey has found the optimal parameters for cold working on steel. Through careful observation and experimentation, they have determined how to increase the endurance of 316L steel by 81.25%.

To improve the properties of metal parts, the metal surface is usually treated with temperature methods -- the material is heated and cooled. 316L stainless steel, however, does not harden in reaction to heat treatments. It can be hardened by cold working, post-processing, and grain refinement treatments

Stainless steel AISI 316L is a common alloy that is used for the production of chemical and aerospace equipment, biomaterials, things like handrails for a pool, and even jewelry. A possible alternative to temperature treatment is shot peening. In this process, small shots are thrust at the surface of a material at a certain velocity. This makes the surface harder and creates residual compression stresses, as well as reduces the grain size. Shot peening materials can include cast steel, glass or ceramic beads, and even cut wire. This study used standard steel shots.

Scientist from RUDN University (Moscow), together with their colleagues, worked to figure out the optimum shot-peening process to increase the endurance of AISI 316L steel.

"AISI 316L stainless steel is widely used in the aerospace, food, and chemical industries, as well as in the production of biomaterials due to its high corrosion resistance and exceptional biocompatibility," said Kazem Reza Kashyzadeh, associate professor of the Department of Transport of RUDN University. "Shot blasting is one of the cold-working processes that makes it stronger. This process takes place without heating -- small pellets hit the surface of the material at a certain speed. Each shot mechanically deforms the material, creating grains. We decided to conduct a comprehensive study of AISI 316L in order to learn more about this process under various conditions."

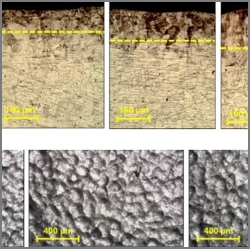

The scientists experimentally investigated 42 types of shot peening with different intensity and different coverage area. Ultimately, they have determined the microstructure of steel after processing, grain size, surface topography, hardness, wettability, and other parameters. The researchers also found optimal peening parameters and studied the residual stress -- the ability not to collapse under the action of cyclic loads -- of stainless steel treated in this way.

The optimal parameters turned out to be an intensity of about 25 (measured using the Almen test by bending the test plate, which is subjected to the same treatment as the material under study) and 1,500% coverage area (that is, the device passes through each area of the material 15 times). It turned out that this makes it possible to increase the fatigue strength of the material by 81.25%.

"To determine the optimal values of the intensity and coverage area, we examined the samples obtained under these conditions. The results showed that shot peening significantly increases fatigue strength. We concluded that it is possible to achieve results close to experimental observations," said Kashyzadeh.

The full results of the work are published in the article, "Influences of Shot Peening Parameters on Mechanical Properties and Fatigue Behavior of 316L Steel: Experimental, Taguchi Method and Response Surface Methodology," in Metals and Materials International. Take a look, and you may find some interesting -- and even beneficial -- information in the details.

Editor's Note: Designfax also suggests you take a look at "Design Guidelines for the Selection and Use of Stainless Steel" available from the Nickel Development Institute as part of their Designers' Handbook Series. Lots of good, basic info in this thorough PDF download (no registration required). A keeper.

Source: Russian Foundation for Basic Research

Published December 2021

Rate this article

View our terms of use and privacy policy